a) Introduction:

- Visual testing is probably the most important of all non-destructive tests. Visual features may be related to workmanship, structural serviceability, and material deterioration and it is particularly important that the engineer is able to differentiate between the various signs of distress which may be encountered. These include for instance, cracks, pop-outs, spalling, disintegration, colour change, weathering, staining, surface blemishes and lack of uniformity.

- Extensive information can be gathered from visual inspection to give a preliminary indication of the condition of the structure and allow formulation of a subsequent testing programme. The visual inspection however should not be confined only to the structure being investigated. It should also include neighbouring structures, the surrounding environment and the climatic condition. This is probably the most difficult aspect of the whole structural investigation or any diagnostic works since what appears obvious to one may not be so to another. The importance and benefits of a visual survey should not be underrated. Often the omission of what appears to be insignificant evidence can lead to a wrong conclusion being made.

b) Before any visual test can be made, the engineer must peruse all relevant structural drawings, plans and elevations to become familiar with the structure. Available documents must also be examined and these include technical specification, past reports of tests or inspection made, construction records, details of materials used, methods and dates of construction, etc.

c) Visual inspection is not confined to the surface but may also include examination of bearings, expansion joints, drainage channels and similar features of a structure. Any misuse of the structure can be identified when compared to the original designed purpose of the structure.

d) For existing structures, presence of some feature requiring further investigation is generally indicated by visual inspection, and it must be considered the single most important component of routine maintenance. It will also provide the basis for judgements relating to access and safety requirements when selecting test methods and test locations.

e) A careful and detailed record of all observations should be made as the inspection proceeds. Drawings can be marked, coloured or shaded to indicate the local severity of each feature. Defects that commonly need recording include:

- cracking which can vary widely in nature and style depending on the causative mechanism

- surface pitting and spalling

- surface staining

- differential movements or displacements

- variation in algal or vegetative growths

- surface voids

- honeycombing

- bleed marks

- constructional and lift joints

- exudation of efflorescence.

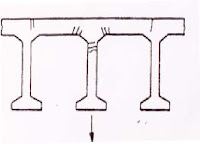

example sketches of typical defect of typical defect found by visual inspection:

Cracks due to differential settlement of central column.

Cracking in columns and beams due to an earthquake.

Reference:GUIDEBOOK ON NON-DESTRUCTIVE TESTING OF

CONCRETE STRUCTURES

No comments:

Post a Comment